Koronka build twin set units for all applications. These pump sets are usually bespoke to your requirements and must take into consideration several factors: the distance pumping, the size of pipe work, the flow rate required and the vertical height so the pump is sized correctly to meet its duty. The examples below show sets which come complete with a control panel, again custom built to suit your requirements and output as well as sized to match the load from the motor.

These units can be either skid mounted on a tray as for use in a plant room or tank mounted as shown below in examples of our Environmental tank range or the Roller Door tank range .

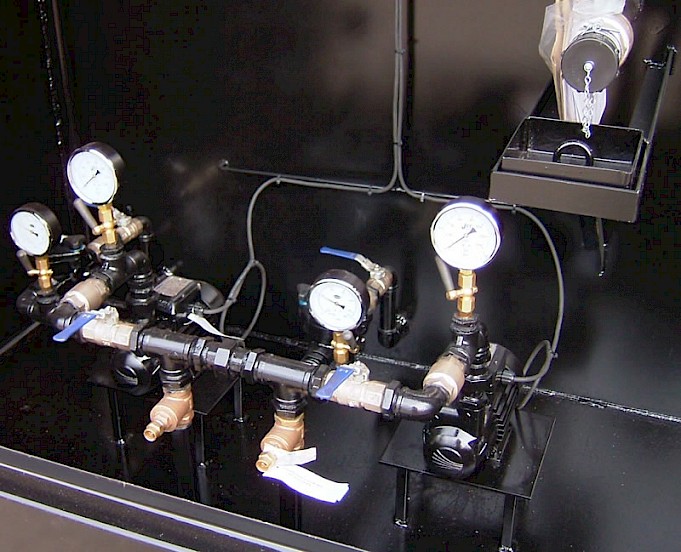

All twin sets are fitted with isolation valves each side of the pump so it can be removed for maintenance should the pump fail. Each line is fitted with a NRV {Non Return Valve} just after discharge so the oil is simply not pumped around and back into the pump inlet. A pressure gauge is fitted as standard on the discharge so that the commissioned engineer can check the setup of the system. All units are provided with a filter of various sizes and types prior to the pump to protect it.

These systems are ideal for pumping to a day tank or around a ring main to feed oil boilers. On the first application a return line is fitted to the system complete with a lock shield valve so you can adjust the pressure and flow rate of the oil going down the line. In the later case a Zwicky pressure regulating value would be fitted to ensure the pressure on the ring main is maintained with excess oil being returned to the top of the tank and not the feed line. It is always best to draw clean, cool, oil and not product that has been through a pump agitating it and allowing it to gas.

30,000 Litre Cylindrical Underground Tanks heading for Hong ...